+7 (3812) 90-16-10 sales@sibek.ru, sibek@yandex.ru sibek-omsk Viber, WhatsАpp:+7(933)442-17-07 Раб. вр.: 9:00 - 18:00

Lider

Description

This equipment is created taking into account features of the repair of motor drives and is designed to restore the geometry of these disks with a diameter of 22 inches.

Ride the motorcycle for many fans is akin to getting a «thrill". Although Biking has certain advantages over a car, but not all obstacles can overcome your «two-wheeled horse". After meeting with potholes and rails for Russian roads, you will visit the qualified workshop of motorcycles.

Restoration and repair of deformed alloy motor drives is one of the most popular services among fans of motorcycles. Buying a new drive is very expensive. So sometimes it is simply impossible to buy a new drive, and raises the question of how to produce a quality repair deformed wheels of the motorcycle. Today, such a repair is possible using the stand for straightening of deformed alloy motor drives «Leader", a design feature which is the presence of two cylinders.

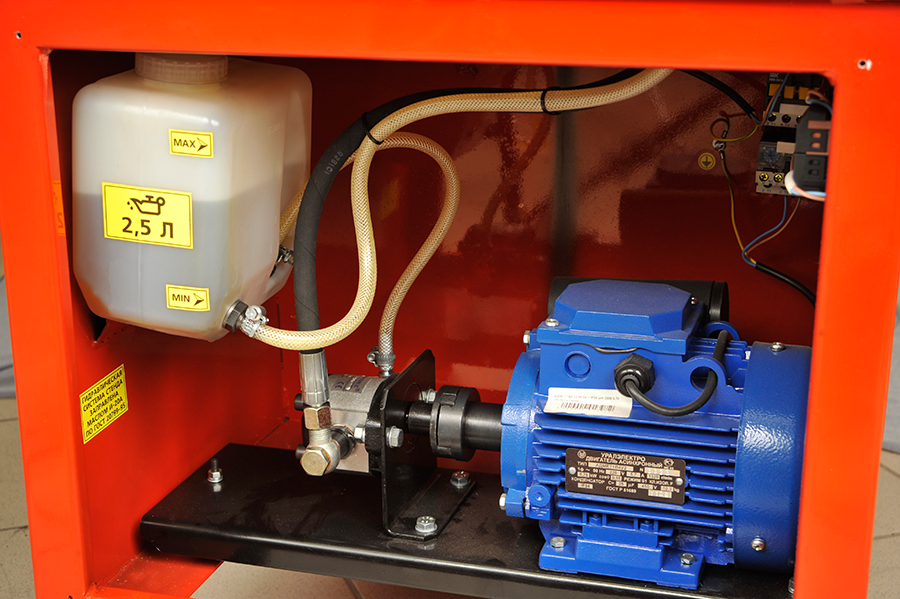

Structurally, the stand for straightening disks «Leader» presents a set of units and assemblies mounted in accordance with the functional connections in a metal case mounted on four pillars, ensures the stability of the stand as a whole. The body of the stand is a metal box with a protective and decorative coating, inside of which is placed a hydraulic unit and tool cupboard. The tool Cabinet is a drawer used to store rightouse nozzles and removable rods of a portable hydraulic cylinders and other tools used in daily work. On the front side of the bracket is a pointer runout. Pointer beats is a rod with a measuring scale and two movable pointers to determine the size and location of runout.

Installing the drive on a bench is on the axle included with the booth together with the conical (centering) bushings and a set of cylindrical (lining) sleeves. The alignment of the disk position relative to the upright, for the purpose of convenience, is carried out by installation of required number of cylindrical bushings on the axle. After the alignment of the drive axle screwed into the nut secured to the front and additionally secured by a clamp.

To edit radial runout of the disk you need to select the area of editing, to fix the drive movable screw stops and depending on the type of damage, to make the appropriate edits mobile hydraulic cylinder. Support mobile hydraulic cylinder may be: directly lower support, a movable angular stop and reset the focus on a vertical pole.

Edit lateral runout of a landing surface drives ("Eight") is carried out using stationary hydraulic cylinders located on the upright of the stand.

Characteristics

| Repaired disc size (rim diameter), inch | от 10 до 22 включительно |

| Disc width, mm | до 200 |

| The voltage, V | 220±10% / 380±10% |

| Power consumption, kW | 0,75 |

| Working pressure in g / system, not more, kgf / sq. cm, not more | 100 |

| Working stroke of a rod of a working hydraulic cylinder, mm | 30 |

| The effort developed by a working hydraulic cylinder, H | 27000 |

| Working stroke stationary hydraulic cylinder, mm | 72 |

| The protection degree of shell | IPXO |

| Class of protection against electric shock, | I |

| Net weight, kg | 173 |

| Gross weight, kg | 206 |

| Overall dimensions min (LxWxH), mm ** | 620х810х1225 |

| Overall dimensions max (LxWxH), mm *** | 690х820х1270 |

| Outline dimensions in packing, mm | 750х1010х1480 |

| ** - stops are not installed | |

| *** - stops are installed in extreme positions. |