+7 (3812) 90-16-10 sales@sibek.ru, sibek@yandex.ru sibek-omsk Viber, WhatsАpp:+7(933)442-17-07 Раб. вр.: 9:00 - 18:00

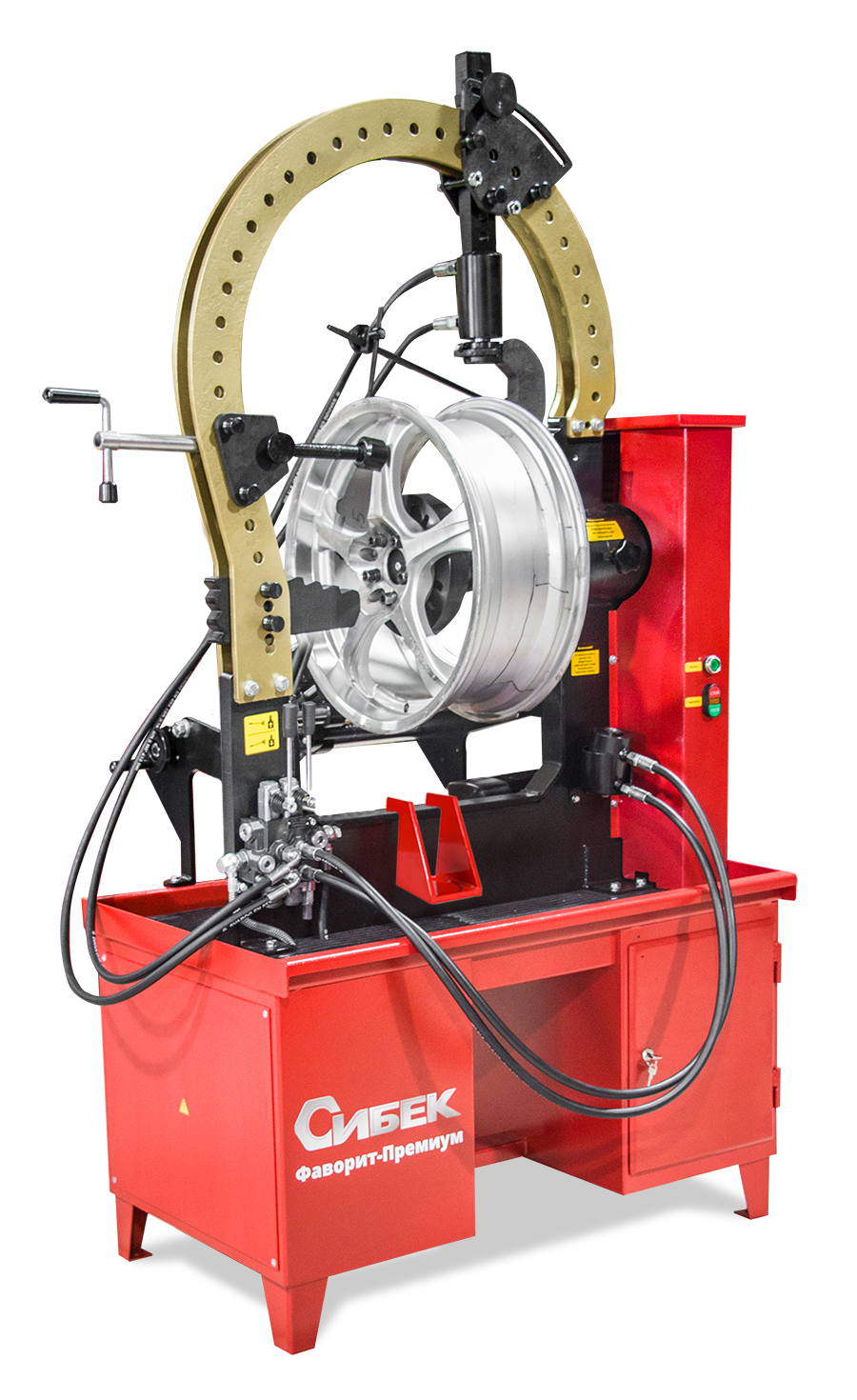

Favorit-Premium

Description

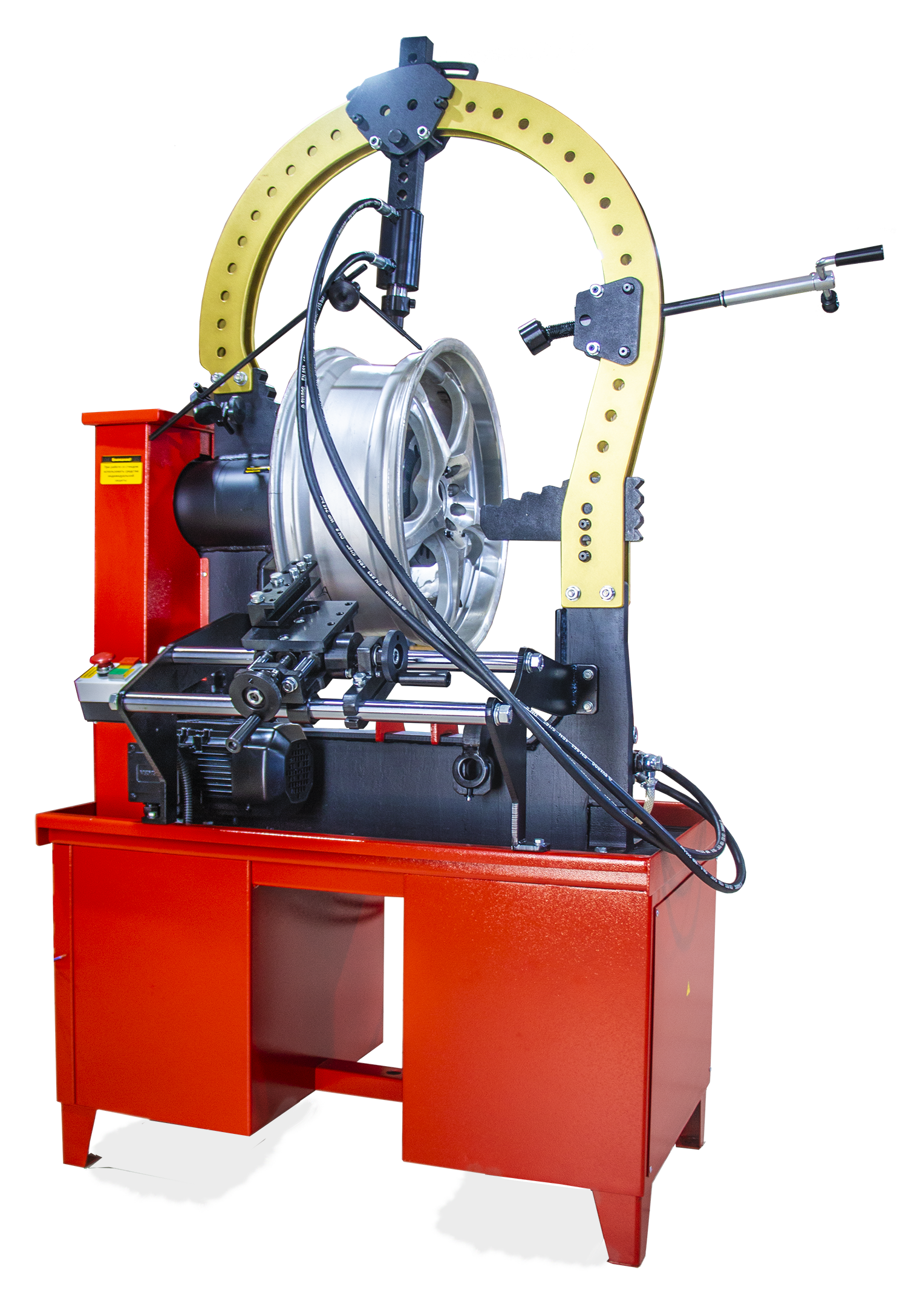

The stand for dressing discs "Favorite-Premium" is designed for dressing especially complex damage to cast and forged alloy wheels, as well as for dressing "Eights" and spokes of wheels from 10 to 26 inches inclusive (from 22 inches use a mobile bracket). The frame is made with permissible loads up to 12 tons. The shaft is made of high-alloy structural steel with increased wear resistance and durability. The stand is equipped with patented special bolts for mounting discs and a reinforced faceplate. Added electric spindle rotation drive designed to make it easier to find the dressing zone disk, which, of course, increases productivity and quality of work.

The updated stand received a special design - a bridge with attachments, installed in place of the classic stops. At the same time, their own are installed on the bridge, special stops that completely replace old ones and expand the possibilities of repair wheel disks. A screw stop is also installed on the bridge, which is necessary for straightening complex damage and damage of the "eight" type, and a special double-sided hydraulic cylinder with capture. The design of the hydraulic cylinder allows it to be fixed in any position and straighten the disc with one hand, without holding the hydraulic cylinder on the weight.

The main advantages of the stand:

- ergonomics to reduce repair time and operator fatigue;

- many accessories and adjustments to make complex repairs;

- two hydraulic cylinders, one of which can be fixed in the required position,

allowing to work "with one hand", making the operator's work safe;

- great effort in the straightening zone;

- the ability to edit large discs up to 26 inches in diameter.

The disc to be repaired is fixed on the faceplate, the group of grooves of which allows fix any disc of the above size. Stand hydraulic drive "Favorite-Premium" allows reaching the maximum force in the dressing zone up to 5000 kg, which, in most cases, allows you to completely restore the geometry of the repaired disk. Complete with replaceable straightening nozzles and working rods. For storage a set of auxiliary tools is provided in the stand design tool box. The working hydraulic cylinders are controlled when by means of a hydraulic distributor with a built-in pressure reducing valve and pressure regulator.The hydraulic cylinders are driven by the pressure generated oil pump. The oil pump located inside the stand body is the basis hydraulic drive of the stand for dressing of disks "Favorite-Premium". Pump rotation carries out an electric motor connected to the pump through a coupling. On the other side of the clamp there is a runout indicator, which is a metal rod with sharp base. The runout indicator is used to clearly identify the place of repair, especially in the final stages of renovation. Turning on the machine spindle rotation by pressing the button located on the front panel. Transfer of moment from the motor to the spindle is made by means of a belt drive.

«Favorite Premium» has two working areas:

- zone changes - in this area is the main work to repair disk damage.

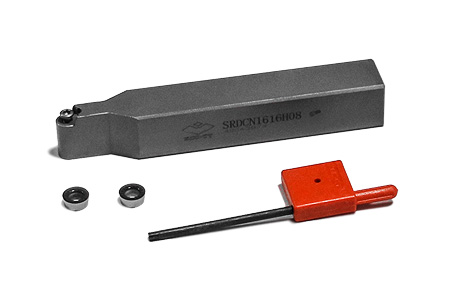

- area finish machining - lathe module is designed to address small defects of the disk, formed in the process of major renovations.

«Favorite Premium» has additional options:

1. A special bridge that replaces the classic stops. Installed on the bridge: two

additional stops, a carriage with a hydraulic cylinder movable along the bridge and a screw stop.

2. Two hydraulic cylinders with a double-lever hydraulic valve with the possibility

simultaneous operation, one of which can be used as a hydraulic stop,

the second can be fixed in any of the available positions.

3. Screw stop for straightening of spokes and damage of type "eight".

4. Enhanced swivel bracket with the installation of additional mechanical stops, which facilitates the installation of the repaired disk on the faceplate, and the focus locks the disk into position.

Characteristics

| Diameter of the mounting shelf of the installed disk, inches | 10-26 |

| Width of the installed disk, inches, no more * | 13 |

| The voltage, V | 380±10% |

| Consumed power, kW | 1,3 |

| Working pressure in the hydraulic system, kgf/sq. cm | не менее 150 |

| Maximum output pressure of a hydraulic pump, kgf/sq. cm | 250 |

| Productivity of a hydraulic pump, l/min | 1,35 |

| Working stroke of hydraulic cylinder, mm | 30 |

| The maximum force developed by the work cylinder, N | 50000 |

| The protection degree of shell | IPX0 |

| Class of protection against electric shock, | I |

| Number of revolutions of a spindle, rpm | 120 |

| Spindle shaft drive | + |

| Existence of a turning caliper | + |

| Net weight, kg | 332 |

| Gross weight, kg | 377 |

| Overall dimensions min (LxWxH), mm ** | 745х1030х1880 |

| Overall dimensions max (LxWxH), mm *** | 935х1195х1990 |

| Outline dimensions in packing, mm | 850х1210x1555 |

| * - turning carriage and stops are not installed; | |

| ** - turning carriage and stops are not installed; | |

| *** - turning carriage and stops are installed in extreme positions. |